Consultation publique sur le projet de : Sungro est présent sur la tourbière de Colombier depuis plusieurs années, en vertu de la Loi sur les mines, comme un nouveau bail doit être obtenu, cette consultation publique est obligatoire. L’extraction de la tourbe est uniquement pour alimenter notre usine de transformation et d’ensachage de tourbe qui est situé à l’adresse : 1000, rue Principale, Colombier, QC. G0H 1P0.

CA_Colombier description

Consultation Publique Colombier Publication 11 juillet 2018

Author: Jan Perez

Managing Low pH in Growing Media for Reliable Crop Performance

Low pH can cause serious production problems for growers. Learn steps to determining low pH in growing media, how to properly sample for accurate testing and the best options for raising growing media pH. This valuable knowledge will help growers maintain the right growing media pH for their crops to ensure reliable production results.

Three Steps for Determining Low pH

Know Optimal pH for the Crop

Before deciding whether growing media pH is too low, the grower must determine what constitutes low pH for a given crop. For example, if geraniums (Pelargonium spp.) are the main crop, the desirable pH during production should be in the 5.8 – 6.5 range. Or, if the crop is calibrachoas, petunias, or pansies, the optimal pH during production should be more in the 5.2 – 5.8 range. Growing media with low pH is generally an issue for plants that are sensitive to excess minor nutrients, which are more available at lower pH ranges.

Know Growing Media pH

Once the desired pH range for a crop is determined, growers must look at the pH of their growing media. Media pH values can vary widely due to a number of factors. The main factors influencing growing media pH are age, ingredients, moisture levels, and storage temperatures. The grower must have a general idea of what the growing media pH will be during production. Media may have an out-of-the-bag pH that is lower than the desired optimal range, but once in production, it should rise within the desired range in 7 to 14 days, assuming water quality and fertilizer selection have been taken into account.

Know Irrigation Water and Fertilizer pH

Water quality and fertilizer also impact media pH. The pH of irrigation water can vary widely. Highly alkaline water leads to a pH increase. Fertilizer ingredients also impact pH. High nitrate and calcium fertilizers are more alkaline and tend to increase pH over time. High ammonium fertilizers are more acidic and will immediately cause a decrease in pH, followed by additional pH lowering over time.

Testing for Low pH

So how can one determine if the pH is too low? The grower can run tests over time on the unused mix to determine if the pH rises after initial wetting. Generally, growing media that has been wetted down with irrigation water will show a pH increase of 0.3 to 0.5 or more after 24 to 48 hours. If testing shows this expected pH increase, the media should eventually get to the desired range. Media pH can continue to rise slowly over the next 7 to 14 days, but generally if we see the expected increase after 24 – 48 hours it is safe to assume that media pH will be adequate for crop production. If out-of-the-bag growing media pH is in the 5.4-6.0 range, it should be adequate without further testing.

Sampling Methods for Testing

Collecting proper samples is essential in helping growers determine the pH of growing media. Packaging formats determine the sampling method. For small formats, such as 2.8 cubic foot bags or 3.8 cubic foot bales, the best samples should represent a composite from a few unused bags or bales. For a small-format composite sample, gather equal samples from 2 or 3 bags, being sure to collect from the middle of the bag or bale, and then combine them. For large formats, such as 55 cubic foot bales or 110 or 120 cubic foot towers, collect composite samples of equal size from a few areas of the bales or towers.

Growing media samples may also be taken from pots during production. To test used mix in production, take equal samples from the middle of numerous pots to create a composite sample for testing. Avoid sampling from the very top or bottom of the pots.

Different volumes of media should be taken, depending on whether you are testing once or over a period of time. For one-time testing, a quart-sized composite sample is adequate. For testing over time, a gallon-sized composite sample is better.

Label samples to maintain correct testing information and match testing results. Labels should contain the following information: date, type of mix, production code from bag or bale labels, and any special notes regarding the mix. Take notes! All of the information on the label should tie back to the total information of the sample.

If samples are to be sent to a lab, send them overnight or via 2-day air to make sure you get results in a reasonable amount of time. Sample at the beginning of the week to avoid having samples sit over a weekend.

Growing Media pH Testing Methods

There are two main options for testing media pH: on-site testing or lab testing. On-site testing provides immediate results and allows the grower to control the testing process. Lab testing reduces labor input and provides a more complete analysis, including data on all major nutrients. Both methods are recommended. Test on-site, but also send some samples to a lab to support on-site results and to get a more complete analysis of the growing medium.

When testing on-site, a simple and repeatable testing method is achieved by creating a 2:1 dilution. This means adding 2 parts distilled or deionized water to 1 part growing medium. It is easier than the saturated media extract method, as it eliminates the subjective determination of when a mix is “saturated”. After mixing the samples, allow them to sit for 15-20 minutes at room temperature, then test the pH and electrical conductivity (EC) if you have an EC meter. Stay consistent in the time you allow the sample to sit.

Continue to test the pH of your growing media. Test media before using it in production, and test it again 7 -10 days after initial watering. Then continue to test on a weekly or bi-weekly basis during crop production. Track your results and review them from year to year. Retest immediately if your results change dramatically to make sure you are not experiencing a test error.

Options for Raising Growing Media pH

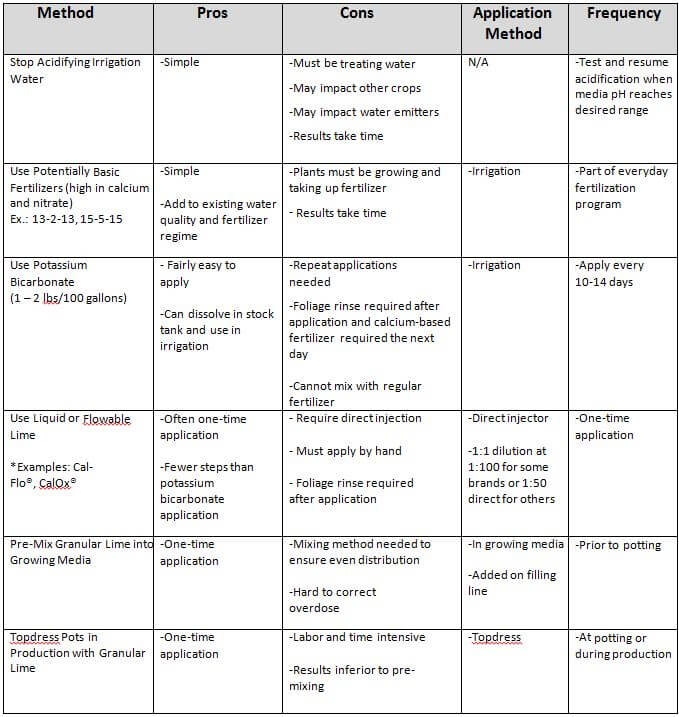

Table 1. Options for raising growing media pH.

There are a number of options when dealing with low pH in growing media. (The different possibilities are listed in Table 1, along with the pros and cons of each method.) The decision on which method (or methods) to use will depend on available labor, greenhouse conditions, and grower preference.

The two easiest options are to stop acidifying water or use potentially basic fertilizers, but they may not provide a quick enough pH change, especially for crops requiring high pH. The use of potentially basic fertilizers should be part of any of the other choices offered in the table.

If a low pH issue is observed prior to potting, lime can be added to the growing media on the filling line, if possible. This will have the best overall impact. Test various rates, but incorporating 2-3 pounds of lime into one cubic yard of mix should bring the mix pH up about 0.5-0.75, depending on the type and coarseness of the lime. Calcitic lime will increase the pH faster, but it will not last as long as dolomitic lime. Topdressing with lime is another possibility, if the growing media is already in the pots or the crop is already in production, though the impact on pH may not be as great.

The addition of potassium bicarbonate when the mix is already in production is relatively easy, but it offers only a temporary solution. It may be a good choice if a grower feels that the fertilizer regimen will eventually bring the pH up, but they need a short-term quick fix. Otherwise, the addition of potassium bicarbonate will need to be repeated every 10-14 days to keep the pH up. Rate for potassium bicarbonate is 1 to 2 pounds per 100 gallons of final solution (1 to 2 pounds per gallon for a 1:100 injector). Some growers have reported issues with potassium bicarbonate in the stock tank when water pH is above 7. Do not combine potassium bicarbonate in the same stock tank with the regular fertilizer!

The final option would be to use a flowable or liquid lime addition. This can be done when the crop is already in production. Examples of flowable lime are CalOx® and Cal-Flo®. They are generally direct-injected from the container at a ratio of 1:100. This should provide around a 0.5 pH unit increase. CalOx® can be injected at 1:5 ratio, providing a greater pH increase. If a higher pH increase is preferred, multiple applications can be made 7-10 days apart, or the product can be diluted in a large tank and applied with a water pump. These products can cause issues with emitters, so they are commonly applied by hand with a hose and regular breaker.

Sun Gro Media Testing:

Sun Gro’s grower technical specialists exist nationwide. Find your state’s Sun Gro contact by visiting http://www.sungro.com/tools-services/grower-technical-services/. To read a full list of our testing options and sampling methods visithttp://www.sungro.com/tools-services/analytic-testing/.

Gro Your Own! Growing Business through Edible Gardening

Edible gardening is hot! Lawn and garden spending reached $36.1 billion dollars in 2015 according to the National Gardening Survey, bouncing back from a five-year low. In 2015, the average homeowner spent $401 per household on yard or balcony gardens, as opposed to an average of $317 in 2014, and the numbers continue to grow. Heightened interest in green living, healthier eating, and food independence has driven this trend, inspiring homeowners to favor natural and organic growing methods. To support this growing industry, Sun Gro® Horticulture created its Gro Your Own™ edible lifestyle marketing campaign for OMRI Listed® skus representing its premium Black Gold®, Fafard®, and Sunshine® brands.

Edible gardening is hot! Lawn and garden spending reached $36.1 billion dollars in 2015 according to the National Gardening Survey, bouncing back from a five-year low. In 2015, the average homeowner spent $401 per household on yard or balcony gardens, as opposed to an average of $317 in 2014, and the numbers continue to grow. Heightened interest in green living, healthier eating, and food independence has driven this trend, inspiring homeowners to favor natural and organic growing methods. To support this growing industry, Sun Gro® Horticulture created its Gro Your Own™ edible lifestyle marketing campaign for OMRI Listed® skus representing its premium Black Gold®, Fafard®, and Sunshine® brands.

This NEW edible lifestyle campaign employs promotional how-to and product videos, trade ads, contests & sweepstakes, and web articles to help homeowners grow outstanding food crops with Sun Gro’s OMRI Listed® products. Gro Your Own™ promotional materials and resources allow retailers to better promote the Sun Gro products they sell. And, the campaign’s focus on year-round edible gardening seeks to extend the growing season and boost sales in the fall and winter, when most edible gardening subsides. This is an asset to independent garden centers that remain open through the year or exist in states with milder winters.

Videos and Web Articles

The Gro Your Own™ video series offers practical guides to edible gardening and features professional horticulturist and edible gardening expert, Jessie Keith. The short videos cover a variety of topics, from amending soil to growing artichokes and container tomatoes. Each is designed to offer accessible yet expert information to gardeners at all experience levels.

Last year over 375,000 gardeners accessed online gardening articles on Sun Gro retail webpages, with edible gardening topics being the most popular. Over 900 expert-driven gardening articles, written by nationally and regionally recognized horticulturists, cover many popular edible gardening trends. They also promote best-use practices and show great gardening results using Sun Gro retail products.

Videos and articles also create promotional opportunities for retail vendors. Direct your customers to Black Gold, Fafard, or Sunshine Advanced websites to help them grow better with Sun Gro.

Contests and Sweepstakes

Everyone loves a chance to win! That’s why we created a new series of bi-monthly Black Gold contests and sweepstakes designed to get the public excited about gardening. These promotions have quickly gained ground, since they were first launched February of 2017!

Black Gold sweepstakes winnings are made in partnership with other respected horticultural companies, including Gronomics®, Smart Pot®, Proven Winners®, and High Mowing Seeds. We have offered everything from raised bed kits to fall vegetable garden packages that engage and motivate our customer base to consider new products and ways to garden. Our winners follow up and share their successes with their winnings, inspiring further engagement and interest in our sweeps products. (Interested in partnering with us? Send an email to Bruce Adams.)

Garden photo contests have offered Black Gold customers another opportunity to win while showing off their beautiful gardens and produce! These have proven to be a great way to show how average gardeners find success with Black Gold.

(Visit our Black Gold Contests and Sweepstakes page to get the latest updates.)

Trade Ads

Gro Your Own™ trade ads in top growing magazines give our products and campaign further visibility and leverage. They are designed to resonate with gardeners seeking to grow their own garden-fresh food.

High-Performing OMRI Listed® Mixes and Amendments

Gardening success starts with great soil, and success yields repeat customers. Our diverse OMRI Listed® mixes and amendments are proven to help gardeners increase food production, naturally and organically. And, select products contain sustainably sourced and innovative ingredients, such as coconut coir, earthworm castings, and our proprietary blend of endomycorrhizae. Our mixes also contain Sun Gro’s patented Silicon RESiLIENCE®. Retailers and gardeners can also visit the our new website and product database to find natural and organic products that best fit their needs.

Gardening success starts with great soil, and success yields repeat customers. Our diverse OMRI Listed® mixes and amendments are proven to help gardeners increase food production, naturally and organically. And, select products contain sustainably sourced and innovative ingredients, such as coconut coir, earthworm castings, and our proprietary blend of endomycorrhizae. Our mixes also contain Sun Gro’s patented Silicon RESiLIENCE®. Retailers and gardeners can also visit the our new website and product database to find natural and organic products that best fit their needs.

Eleven OMRI Listed® mix and soil amendment skus will be promoted in the Gro Your Own™ campaign

Mixes

- Black Gold® Natural & Organic Potting Mix with RESiLIENCE®

- Black Gold® Seedling Mix with RESiLIENCE®

- Black Gold® Waterhold Cocoblend Potting Mix with RESiLIENCE®

- Fafard® Natural & Organic Potting Soil with RESiLIENCE®

- Sunshine® Natural & Organic Professional Growing Mix with RESiLIENCE®

- Sunshine® Advanced Mix #4 Growing Mix with RESiLIENCE®

- Sunshine® Advanced Rain Forest Blend with RESiLIENCE®

- Sunshine® Advanced Ultra Coir with RESiLIENCE®

Soil Amendments

- Black Gold® Just Coir

- Black Gold® Earthworm Castings

- Black Gold® Garden Compost Blend

© 2016 Sun Gro Horticulture Canada Ltd. All rights reserved. No materials contained herein may be duplicated or used in any way without the express written permission of Sun Gro Horticulture or its legal representatives.

® Black Gold is a registered trademark of ODIN Enterprises II, LLC. Used under license.

® Fafard, Sunshine Advanced, Sunshine and Sun Gro are registered trademarks of Sun Gro Horticulture Canada Ltd.

™RESiLIENCE and Our Expertise is Growing are being used as trademarks of Sun Gro Horticulture Canada Ltd.

Not all products available in all markets.

Sun Gro® Horticulture & Proven Winners® Form A New Sales & Distribution Partnership

Sun Gro Horticulture and Proven Winners are pleased to announce that effective immediately Sun Gro will produce, sell and distribute Proven Winners branded Premium All-Purpose Potting Soils, Premium Water Soluble Plant Food, and Premium Continuous Release Plant Foods, available to garden centers from multiple stocking distributors. The Proven Winners branded Potting Soils and Plant Foods are a strong addition to Sun Gro’s very successful IGC-oriented brand offering: Black Gold®, Fafard®, Sunshine® and Sunshine® Advanced.

Sun Gro Horticulture and Proven Winners are pleased to announce that effective immediately Sun Gro will produce, sell and distribute Proven Winners branded Premium All-Purpose Potting Soils, Premium Water Soluble Plant Food, and Premium Continuous Release Plant Foods, available to garden centers from multiple stocking distributors. The Proven Winners branded Potting Soils and Plant Foods are a strong addition to Sun Gro’s very successful IGC-oriented brand offering: Black Gold®, Fafard®, Sunshine® and Sunshine® Advanced.

This is a huge opportunity for garden centers to have easy access to these vital gardening components specifically formulated to make Proven Winners plants perform at their peak levels for home gardeners. Retailers will be able to purchase Proven Winners branded Potting Soils and Plant Foods through Sun Gro’s extensive and very successful U.S. distribution network.

Initial IGC warehouse sales will be concentrated through four distribution partners: Arett Sales, BFG Supply Company, Griffin Greenhouse Supplies and Foster’s Inc. Additionally, these items will continue to be available for purchase from Four Star Greenhouse and Pleasant View Gardens, owners of the Proven Winners brand.

Presently, these items are only available in the United States.

Proven Winners is recognized as the #1 Plant Brand® and market leader in North America. www.provenwinners.com

Sun Gro Horticulture Inc. is North America’s leading supplier of soilless growing mixes to professional greenhouse, nursery growers and retail mixes for independent garden centers. www.sungro.com

For more information, please contact:

Bruce Adams, Sun Gro Horticulture

413-523-0725

bruce.adams@sungro.com

Dave Konsoer, Proven Winners

312-501-8136

dave@provenwinners.com

For more ordering and packaging details, click here.

Air Porosity and Water-Holding Ability of Media Components

Most soilless growing media are composed of multiple components with distinct physical properties that fit together to form pore spaces of various sizes. Coarse particles create larger pores (macropores) that maintain air spaces and facilitate drainage, while fine particles create smaller pores (micropores) that hold available (and unavailable) water. Each component functions to meets a series of essential requirements. The media formulation is equally important because individual components will not retain their original porosity when combined. The combination of media components amounts added, and their distribution determines the character and porosity of a medium.

Why should growers be concerned about growing medium components, formulations, and essential requirements? Ensuring plant roots have sufficient air, water, and the right balance of available nutrients safeguards crop success. Stressed plants are more susceptible to pests and diseases as well as environmental stresses, which increases maintenance costs and decreases revenue.

Media Purpose and Properties

The purpose of growing medium is to support plants and their roots. A well-formulated medium creates a stable substrate that provides the right characteristics for a crop. Essential requirements must be met for the medium to offer the right amount of available oxygen and water for plant-root uptake while also providing a reservoir of available nutrients.

The essential requirements of a growing medium can be broken into two categories—physical and chemical requirements. The physical requirements are impacted more by component selection. The chemical requirements are impacted more by water and fertilizer selection and include pH and soluble salts. These requirements must be met to facilitate healthy root systems for strong growth.

The physical properties of a medium are generally dictated by the coarseness and fineness of its component particles. Key physical properties include bulk density, texture, porosity, available/unavailable water, and decomposition time. The cultural requirements of a crop determine the physical properties of a medium. Getting the balance of physical properties right for a given crop will aid in disease resistance, root respiration, and root development.

The chemical properties of a medium are equally important. Cation exchange capacity (CEC), electrical conductivity (EC), and pH are the three key properties that aid in retaining and releasing nutrients available for plant uptake. A good mix will maintain the right pH for a given crop while holding and providing needed nutrients for uptake.

Air and Water Pore Space

Particle sizes and the spaces they create are fundamental because particle size and distribution dictates the air-holding and water-holding capacity of a medium. Total porosity indicates a growing medium’s volume percentage of pore space. The number of macropores and micropores characterize media pore space.

There are general porosity and air space percentage ranges for soilless media in commercial ornamental production. On average, media has a “normal range” with a total porosity of 75-95%, air space of 10-30%, and container capacity of 65-80%. The recommended air-space range varies by crop: propagation mix should have 10-15% air space, general greenhouse production media should have 15-25% air space, and perennial mix should have no more than 25% air space.

Pores are the spaces between the solid components of the medium. Most soilless growing media contains 60% to 80% total pore space. Pore size determines the rate of drainage and gas exchange. The size and distribution of pores are the most critical factors in developing a growing medium with optimum physical characteristics. The amount of air and water pore space is determined by particle size. Larger or coarser particles have a greater percentage of air pore space, while smaller or finer particles have a greater percentage of water pore space. Adequate distribution of large and small pores is essential.

A mix containing coarse particles has fewer but larger pores. Large pores permit air to reenter the medium following irrigation. On average, most mixes contain 10% to 30% air following irrigation. Despite losing more water more quickly, larger pore spaces offer plants more available water at watering time.

A mix containing fine particles has more but smaller pores and a greater percentage of water pore space. The larger the quantity of water held by a medium, the lower the percentage of pore air space it maintains. The closer a water molecule is to a solid, the more tightly it is held through the forces of adhesion and cohesion. Therefore, a fine mix may hold more water than a coarse mix, but less water may be available to the plant. In general, the amount of unavailable water is relatively high in soilless growing medium.

Water Holding Capacity Stages and Media Components

Three stages are applied to water holding capacity: saturation, container or field capacity, and wilting or permanent wilting point. At saturation, most pores are full of water during irrigation. Gravitational water drains from the macropores due to gravity, and these pores refill with air. At container or field capacity, gravitational water has drained, and the medium contains available water for plant growth. Capillary action allows the micropores to retain water. At wilting point or permanent wilting point, no more water is available to plants and most plants wilt and fail to recover turgor when irrigated. All water between container or field capacity and wilting point is available water.

Different media components contribute to water holding capacity at various levels. Consider the following ingredients: coir, rock wool, peat, pine bark, vermiculite, perlite, and sand. Each lends unique characteristics with respect to saturation, container capacity, and the amount of water held. For example, components with smaller, finer particles and pores, such as Canadian Sphagnum peat moss, processed coconut coir, and rock wool, hold more water. In contrast, those with larger, coarser particles, such as pine bark, perlite, and sand hold little water. The percentage of each component making up the mix will determine the duration of container or field capacity.

Let’s consider an example of high- and low-bark media and how bark percentage impacts total porosity, container capacity, air space, and bulk density. A high-bark medium (50% peat, 10% perlite, 15% vermiculite, and 25% bark) maintains the following physical characteristics: total porosity of 87%, container capacity 71%, air space 16%, and bulk density 13-16 pounds/cubic foot. A low-bark medium (55% peat, 15% perlite, 15% vermiculite, 15% bark) maintains the following physical characteristics: total porosity of 90%, container capacity 78%, air space 12%, and bulk density 10-12 pounds/cubic foot. The higher bark medium is more heavyweight and maintains a lower container capacity, but it has more air space. As particle size increases, so does porosity.

Container Height and Media Water

Container height also impacts the relative amount of water versus air in a medium. The taller the container, the less evenly water is distributed throughout the container, regardless of the media. Here is how it works.

Water is pulled down through the pot and drainage holes via gravity. Gravity in the container is constant but the gravitational potential at the container’s top is higher than it is at the bottom. Water is attracted to particles by adhesion, cohesion, and capillary and resist gravity. Matric potential, which is a medium’s ability to hold water through adhesion and cohesion, remains constant throughout the container.

As James Altland, Ph.D of North Willamette Research and Extension Center,

Oregon State University writes in the article, Physical Properties of Container Media: “Because of this gradual decrease in gravitational potential towards the container bottom, matric potential is higher at the container bottom and media particles are able to hold more water. This causes water to form a perched water table at the container bottom. The perched water table is a layer of saturation on the container bottom. In contrast, more air and less water exist towards the top of the container. With the same media, the perched water table occurs at the same height, regardless of the container size. Short containers will have the same perched water table as large containers. Thus, a greater percentage of container volume is filled with water. This explains why a taller 5-gallon container holds less water than a shorter 5-gallon container.”

Media Handling and Porosity

Handling impacts media porosity. Not only is it up to the grower to select the right growing media for their needs, they must also correctly manage it. Many handling and management mistakes can damage media structure and performance, resulting in poor plant growth.

Over mixing and fluffing or using inadequate equipment for fluffing compressed-bale growing media can damage the structure of various components, which can decrease porosity and structure. Pre-wetting media to 48 to 52 percent moisture at the fluffing stage will help it maintain structure and perform well. On average, media are produced at 35 to 45 percent moisture. Pre-wetting will also help growers avoid irrigation problems, such as water channeling and dry areas in the media.

Media compaction will also decrease the presence of macropores, decrease air space and increase bulk density. Compaction can occur when a medium is manually pressed down at planting time, or when filled pots of flats are stacked. Proper media handling will keep it well aerated will allow it to perform as expected.

Conclusion

When selecting or formulating media for crops, be sure to choose media components carefully and consider the overall formulation with respect to air porosity and water-holding ability. Manage your media well to ensure it maintains the right characteristics and choose the right medium for the right pot size. Making good growing media decisions will ensure plant roots have sufficient porosity for air and water as well as the right balance of available nutrients for success.

Sun Gro’s PAR Vegetable Garden, Since 2000

Back in 2000, the Sun Gro® Horticulture corporate office in Agawam, MA moved to a new site that included a garden. The garden was originally used for display, but eventually, we transformed into the Plant a Row for the Hungry (PAR) vegetable garden. [The Plant a Row for the Hungry (PAR) program was launched in 1995 by the Association for Garden Communicators (GWA) and GWA Foundation as a public service to encourage gardeners to grow fresh produce for community food banks and soup kitchens.] The garden was expanded and upgraded in 2010 and has been yielding produce for our local food pantry ever since.

Over the years, the Sun Gro® PAR garden volunteers/employees have planted, weeded, watered, and fertilized the garden and reaped the harvest. As the company has changed with time, so have our employees who volunteer in the garden. Plenty of longstanding staff have participated in the garden since the beginning, and there are always new employees willing to get their hands dirty to support the effort. Sometimes family members help out, too. It’s a community effort!

More recently, we invited outside volunteers to help keep our PAR garden productive. Our biggest help comes from the horticultural students from Westfield Technical Academy in nearby Westfield, MA. Our garden gives them hands-on training in garden prep and planting, and we are grateful for the help! They come in spring to help us get the garden prepped and sometimes they help plant. They also help at harvest time when we weigh in our crops and deliver them to the Westfield Food Pantry, also in Westfield, MA.

Like most gardens, we have bountiful harvests some years and other years the weather and weeds get out of hand, but it’s not just about our gardening success. Our PAR garden also teaches us about working together and committing time to our local community.

In our best harvest year we weighed in nearly 450 pounds of fresh produce, so we know our garden is making a difference! This year, we plan to do much better. Our volunteers have signed up for 2017 and are scheduled to start planting vegetables in late May. We will also be installing three raised beds (filled with Black Gold® container mixes), with lumber donated from Lucia Lumber Co. Inc. (Agawam, MA), and fencing to keep out unwanted wildlife.

Great American IGC: McDonald Garden Center

Ask anyone in the Hampton Roads area where to go shopping for plants, and they will direct you to McDonald Garden Center. Founded in 1945, the family owned and operated business was started by two brothers with a vision to bring high-quality garden plants and products to the residents of Hampton, Virginia. In 1973, the center was purchased by the Anderson family. Since then, business has grown and expanded into the southside of the Hampton Roads area with the addition of seasonal garden markets as well as the landmark year-round location in Virginia Beach. McDonald Garden Center also offers landscape design and installation services throughout the area.

Gardeners turn to McDonald Garden Center for their wide selection of locally grown, unique garden plants—from bedding and greenhouse plants to trees, shrubs, and vegetables. The center also provides a wide selection of beautiful containers, statuary, fountains, and patio furniture.

McDonald Garden Center is also known for its outstanding garden mixes, amendments, and mulches, and we are proud to say they are some of the best around. How do we know? Sun Gro manufactures the exclusive, private-label potting soils for McDonald Garden Center, as well as supplying them with Black Gold brand products.

If you live in the Hampton Roads area, turn to McDonald Garden Center for their exceptional service and horticultural expertise. They encourage best-practice gardening techniques while offering an enjoyable, plant-filled shopping experience.

Sulfur On Tap

By Shiv K. Reddy –

A recent study shows that irrigation water sources across the U.S. rarely provide sufficient sulfur for greenhouse plants. We searched our lab database, which contains analyses of water samples from all across the U.S, and created a map that represents results from the most comprehensive survey to date on sulfur in greenhouse water. Check out how your state measures up…

Read Sulfur On Tap

Review of Major Growing Media Components

By Dan Jacques and Ron Walden, Sun Gro Horticulture –

The major role of a growing mix is to support the plant, while holding water and nutrients for the plant to use during growth. There are five main components commonly used in making growing media: peat moss, bark, coir, perlite and vermiculite. This article describes the components and outlines desired properties of mixes for various uses in greenhouse production.

Time to Say Sí to Silicon — the Missing Element in Soilless Growing Mixes

Read everything that you need to know about horticultural silicon with this grower to Sun Gro technical specialist Q&A. Horticultural silicon is a water-soluble element that’s readily available to plants.

I’ve been hearing about silicon in plants and want to discuss the subject. Isn’t silicon ubiquitous?

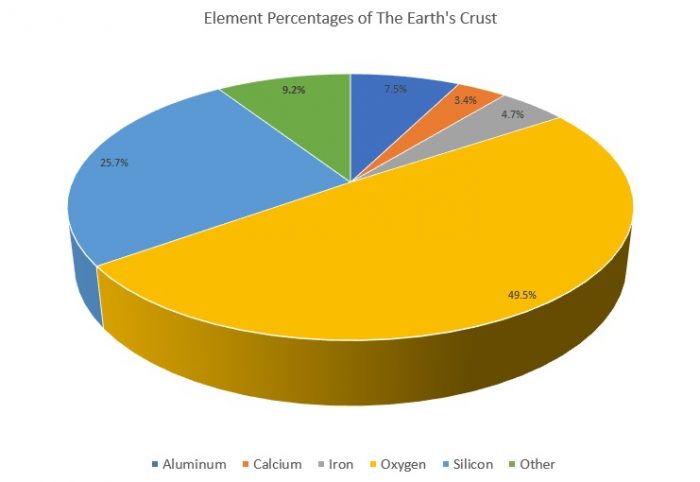

True, silicon is the second most abundant element in the Earth’s crust, where surface soil exists. Plants growing in natural soil are constantly in contact with silicon. Of course, plants don’t indiscriminately take in all of the elements they encounter in soil; they take in elements selectively. Plants do naturally take in and accumulate silicon, which indicates they’re using it. In fact, most plants growing in natural soils take in as much silicon as common nutrients essential for growth, like phosphorus, calcium, magnesium, sulfur. Some plant species take in more silicon than even nitrogen and potassium!

Figure 1: Silicon is the second most abundant element in the Earth’s crust, so not surprisingly plants growing in natural soils have evolved to absorb and use silicon to their benefit.

What about silicon in potting media? Aren’t some potting media components, like sand, perlite, vermiculite, silicon-based?

Virtually no container grower uses natural topsoil in potting media anymore. Container growers use soilless media that’s mostly made of organic materials like peat, bark, coir, etc. These organic materials have hardly any minerals, let alone silicon. Although sand, pumice, perlite, vermiculite, rockwool are technically silicon materials, silicon from these materials is barely available to plants. In fact, silicon content in the plants growing in these soilless media is remarkably lower compared to the same plant species growing in natural soil.

Are my plants deprived of silicon when grown in soilless media?

Yes, compared to the natural world, where silicon is the norm in natural soil and where silicon is an integral part of natural plants, lack of silicon in soilless growing media and in turn plants growing in such media are artifacts and not entirely normal plants!

I’ve been growing plants alright in soilless media without silicon. Is it really needed?

Silicon got neglected— although unknowingly— during the historical and gradual transition from using all field soil to some field soil to completely soilless media in containers. That you can grow plants without silicon didn’t help either in silicon getting any attention. Silicon is not essential to plants, meaning plants can grow, flower and finish their life without silicon. You don’t see any obvious symptoms on plants when silicon is deficient, so you don’t pay any attention to silicon. Silicon is a beneficial element. It is similar to fluoride for our teeth. Fluoride is not essential for humans, but fluoride is beneficial in that it strengthens tooth enamel making it less vulnerable to cavities.

Does silicon strengthen plants? Does it have other benefits?

In nature, plants have evolved to absorb and use silicon to become not just structurally but also biochemically strong. Plants use silicon to cope with a variety of adverse conditions they encounter— such as pest attacks, strong winds, water shortages, toxic elements, etc. Think of plant using silicon to build a more solid house for itself against the huffs and puffs of adversaries!

What actually happens when silicon is available to the plants?

Plant roots take in silicon that is in the form of silicic acid and transport majority of it to the shoot along with the water stream. Along the way, some silicic acid is deposited in the roots and some in the xylem in the shoot. After reaching leaves, silicic acid is deposited in the walls of epidermal cells, just beneath the cuticle. As water is lost through transpiration, silicic acid concentrates and polymerizes to

solid silica gel. This results in the formation of a double layer of cuticle-silicon. The solid silica gel bodies are called phytoliths or plant opals, as they give toughness to plant tissues. In fact, fossilized phytoliths are what archeologists find years later and use to identify what kind of plants existed at a site!

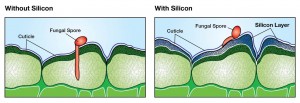

Does the double layer of cuticle-silicon in plants act as armor?

Yes, to enter into a plant, fungal spores or insects have to puncture and penetrate the plant surface or cuticle first. When there is a silicon-reinforced barrier there, the resistance to the puncture increases and the progress of pest entry, in turn the incidence of pest attack decreases. The solidified silicon wears off mandibles of insect larva when they chew plant tissue, thereby limiting plant damage by insects.

You mentioned silicon protects plants biochemically, too. How?

Right, solidified silicon acting as an armor is not the whole story in silicon’s role in protecting the plants. When pathogen fungal spores attempt to penetrate the leaf, the fraction of silicon that’s still in solution form there— that’s silicic acid not yet solidified— triggers the synthesis of organic defense compounds within the plant by the plant itself. These compounds also obviate the fungal infection process. For this kind of protection, silicon in the plant should be in the form of silicic acid during the pest attack, because silicon that’s already solidified cannot reverse back to silicic acid. Solidified silicon within the plant cannot move from one location to another either— thus, a continuous availability of silicon is needed for growing plant tissues.

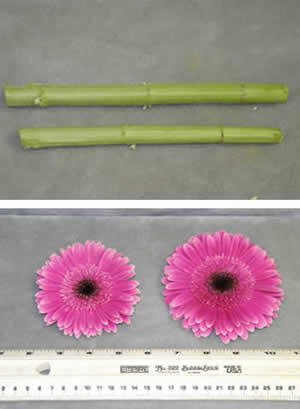

How do silicon-reinforced plants compare to those grown in standard mixes?

Yes, in nature, plants don’t want to collapse. In nature, plants absorb, deposit and solidify silicon in cell walls to gain structural rigidity so as to be erect and strong and resist falling during strong winds. The same effect of strong stems translates to fewer branch breaks during handling and shipping of your container plants, which are often top heavy. Such strong stems also help in cut flowers not being bent in floral arrangements. In nature, silicon-solidified stiff leaves hold wide and intercept and capture more light. Such an effect counteracts straggly plants with soft, droopy leaves, which often occur from the use of high nitrogen fertilizers in greenhouse plants. The silicon layer formed below the cuticle in leaves acts as a barrier against water loss from transpiration through cuticle. This effect reduces withering of leaves and prolongs the shelf life of container plants at retail stores.

Are there any other positive effects from silicon?

Silicon has such diverse effects on plants that it’s difficult settle on just one effect of silicon in any plant species. Silicon mitigates toxicity from micronutrient metals like manganese, copper, zinc, iron and balances their levels in plants. For example, you may have seen ugly brown spots on foliage of ornamental plants— on pothos, palms, etc.— due to toxic accumulation of oxidized manganese, coming from high manganese bark mix or low pH in growing media. Silicon prevents the buildup of such spots of toxic concentrations of manganese by distributing manganese evenly, thereby suppressing the appearance of ugly spots on ornamental plants. Similarly, silicon prevents copper toxicity, which plants can encounter from composts, fungicides or ionization of irrigation water. You may even have seen a copper toxicity symptom in your growing and probably mistook it as iron deficiency— for instance, chlorosis on the leaves of petunias! Interestingly, silicon ameliorates true iron deficiency too, modulating iron in the plants under iron deficiency conditions, resulting in significantly greener leaves and slower senescence. Silicon also helps plants cope with high salinity or high EC by reducing the level of salts getting into the shoots by blocking salt flow through the roots. This effect is especially important if your irrigation water is not of high quality or you are recycling your water, which tends to have high salinity.

Based on research, are silicon benefits more obvious when plants face adverse conditions?

When the going gets rough, with silicon, plants get tough! As you perceived, effects of silicon are not so evident or muted when plants are growing under benign conditions, but the effects become more apparent when plants come under stress. Stress is a universal condition all organisms face, so like you, plants do face stress conditions in real world, even in commercial greenhouse growing. In response, when plants have access to silicon, they use silicon as needed, sometimes acquiring silicon only under stress and reacting adaptively to those stresses. Effects of silicon are realized even better when a stress develops gradually, approximating the stress plants encounter in nature.

Greenhouse-grown plants are always weaker than those grown outdoors. Could some of these growth differences be due to a silicon deficiency in plants grown in soilless media?

Observations on plants without and with silicon have been corroborated in laboratory experiments. In fact, such pragmatic observations on plants grown in the field soil versus in the soilless mixes in greenhouses are kindling the attention to silicon from greenhouse growers.

Can field-grown plants benefit from the addition of horticultural silicon?

It depends on soil type and attributes. For example, Florida farmers get positive responses in sugarcane quality when they apply silicon, and the application of silicon to rice is routine in Japan. This is because sugarcane in Florida is largely grown in the mucky soils of the Everglades, which are highly organic and silicon poor— just like your organic potting media. Likewise, Japanese rice farmers started using silicon long ago because they realized that their staple food crop— rice— wasn’t growing well without additional silicon due to the high organic matter in rice paddies. In either situation, adding sand to the soil would not help because silicon in this form is unavailable to plants.

Mineral soils may also benefit from applications of horticultural silicon. Native silicon, even in mineral soils, can be depleted due to continuous, repeated cropping. Of late, silicon applications are also becoming common in hydroponic crops, like cucumber, tomato, rose, etc.

Don’t some plants accumulate more silicon than others?

Yes, the amount of silicon accumulated varies not only among the crops, but even within the varieties of the same crop. Some varieties of rice accumulate silicon up to 10% of their dry weight. However, even 0.5% silicon in any plant is still similar to the percentages of essential nutrients like phosphorus, magnesium, sulfur. There are also differences among crops in their interaction with silicon. For example, there are variations in how much silicon is deposited in which plant organ (root, shoot, leaves, flowers, bracts, etc.) and where in the organ (lower leaves, upper leaves, lower or upper surface of a leaf, edges or middle of a leaf, etc.). The form (size, shape, texture) of silica structures or opal phytoliths formed among plants is also diverse. Uptake of silicon by plants differs under different conditions (summer versus winter). Such intrinsic differences in silicon accumulation patterns in turn influence the effects of silicon in various plants to various degrees under various conditions. Thus, less silicon in a plant doesn’t mean it is less effective functionally or less beneficial. For instance, lettuce accumulates little silicon (0.05%) but still just that much silicon somehow alleviates manganese toxicity, a plague in heading of lettuce. What exact role silicon plays in all the plant species under what context is still not fully understood. As a university professor put it, the biochemistry of silicon is the proverbial riddle wrapped in a mystery inside an enigma!

Though we don’t yet understand the dynamics of silicon in plant life fully, I presume there would be some role for silicon in all the plants since there is no ‘no-silicon’ plant in nature! So far, the subject of silicon has been deficient in my mind and silicon has been deficient in my plants. Now, I want to insure all my plants have silicon available to them just as in nature. So, how can I provide silicon to plants growing in soilless potting mixes? Not through silicon chips, I presume!

Sorry, no luck recycling your old computer chips to provide silicon to the plants! Providing silicon effectively to the plants growing in soilless media is a significant challenge, which is another reason why use of silicon in soilless culture is hampered. Remember that silicon is abundant on the Earth, so not surprisingly there are many natural silicon compounds, as well as industrial byproducts. However, just because a compound has silicon in its name doesn’t mean it’s a suitable source for plants in soilless media. Similarly, a material that contains more silicon doesn’t mean it provides more silicon to plants. After all, we just learned that plants hardly obtain silicon from sand, which literally is silicon! If you want to evaluate a silicon source, remember labs don’t test for plant-available silicon routinely.

Providing silicon to plants through irrigation is complicated too. Silicon sources for such use are not stable and when mixed into a regular feed solution, precipitation and severe clogging of irrigation nozzles occur. Such a precipitation interaction occurring in the growing media can obstruct watering and drainage of the growing media.

Roots of plants growing in natural field soils explore large volume of soil for silicon. However, roots of plants growing in containers can explore just the media limited to the container. Thus, a silicon source in soilless media in containers should be sufficiently available for the plants in the containers. The source should be pure and free of contaminants. It should be consistent from batch to batch. It shouldn’t compromise physical and chemical qualities of the growing media. Of course, low cost helps. Such a silicon source already embedded in the growing media would be convenient, so you don’t need to change your existing practices of watering, fertilizing, etc. Promising efforts have been made to embed such a silicon source into soilless growing media. Discuss with your growing media supplier.

Well, with fluoride embedded toothpaste, there has been decline in tooth cavities. With silicon embedded soilless media, there would be a decline in damage to plants from pests and other stresses. With silicon integrated into soilless growing, plants growing in soilless media can emulate plants in nature in building up their inborn defenses. Such plants would need less pesticides and growth regulators based on University research. In our production of crops in soilless media, we desire such simple and natural practices.

Though the subject of silicon in plants still poses many fascinating questions, we’ve come a long way in our understanding of it and now there is enough evidence showing silicon benefits plants. So, silicon can now become an integral part of soilless growing technology and then, yes, plants in soilless culture can grow naturally— just like in nature!

(The views expressed here are not necessarily those of Sun Gro. A version of this article appeared in GrowerTalks May 2014.)

Silicon potting mix was one of the new products developed in the 1990s at the then Sun Gro R&D facility in Warwick (New York). Dr Shiv Reddy, along with the late Dr Paul King, developed and patented a novel soilless growing media that includes silicon. Dr Todd Cavins, who had researched silicon effects in greenhouse crop production at Oklahoma State, joined Sun Gro in 2005 and renewed the interest in silicon at Sun Gro.

Since those early days, numerous investigations at universities, government departments of agriculture across the world and 6 international conferences on silicon in agriculture plus symposiums, workshops show growing importance of silicon in plant life. All this evidence triggered the Association of American Plant Food Control Officials (AAPFCO) to look at silicon in a new way and designate and accept it as beneficial substance in 2012.

In 2013, the new management at Sun Gro, while reviewing the assets of Sun Gro, realizing the importance of silicon in horticultural growing, decided to update the silicon mix research at the current Sun Gro Discovery Centre for research in Anderson (South Carolina) and offer the product to the horticultural industry.

On the eve of this new product launch at Cultivate 14 in 2014, Shiv presents a thoughtful conversation, answering the questions that growers may have and perhaps they didn’t know they have!

If you have further questions, please contact a Sun Gro Technical Specialist.